Tooling

Punches and dies constitute the key element of the tabletting process. They impact the final appearance…

CS-2500 Level 5

The CCS CS-2500 Level 5 Control System elevates tablet press operations to new heights. Designed for compatibility with various models, including those from Stokes, Fette, Korsch, and Hata, it offers a comprehensive solution for managing tablet presses. This advanced system not only includes standard press controls but also excels in generating detailed, customizable reports, covering production data, parameter changes, and alarms. Equipped with a development license of XLReporter, users can tailor reports to specific needs, ensuring precise tracking and analysis of production processes. Its use of off-the-shelf components and Allen Bradley technology makes it user-friendly and easy to maintain, while also complying with 21 CFR Part 11 standards for data collection and E-Signature.

CS-2000 Level 4

The CCS CS-2000 Level 4 Control System is a versatile solution for managing Stokes tablet presses and other OEM models. It features standard programming that unlocks all functions of the presses, enhancing operational efficiency. The system is built with off-the-shelf Allen Bradley components, making it cost-effective and easy to maintain. With Allen Bradley ControlLogix PLCs and FactoryTalk View HMI interface, it offers complete control and precision. The system is compliant with 21 CFR Part 11, ensuring reliable data collection and electronic signatures. Its design prioritizes non-proprietary components for high reliability and easy part replacement, supported by advanced features like Advantech Industrial PC, Netbiter Remote VPN, and precision servo motors.

CS-500 Level 3

The CCS CS-500 Level 3 Control System is a robust solution for managing Stokes tablet presses and is adaptable to other brands. It simplifies operations with its Basic CS-500 programming, allowing users to monitor and control essential functions effectively. This system is not only user-friendly but also cost-effective, incorporating Allen Bradley components to reduce the total ownership cost. Its design features the latest technology, including Allen Bradley ControlLogix PLCs and a FactoryTalk View HMI interface, ensuring comprehensive control over the tablet press while maintaining ease of maintenance and part replacement.

CS-400 Level 2

The CCS CS-400 Level 2 Control System brings a new level of efficiency and ease to encapsulation equipment operations. It’s tailored for Index Encapsulation Equipment but adaptable to machines from any vendor. With its Standard CS-400 programming, users gain comprehensive control over basic functions. The system’s use of Allen Bradley components, including ControlLogix PLCs and Power Flex 525 Motor Drives, ensures reduced costs and maintenance ease. It also includes a FactoryTalk PanelView HMI interface for seamless operation, presenting a reliable, cost-effective solution for encapsulation machine management.

CS-200 Level 1

The CS-200 Level 1 Control System from CCS is engineered for straightforward and efficient management of all models of Index Encapsulation Equipment, and it’s adaptable to encapsulation machines from any manufacturer. Its ease of use is a standout feature, thanks to the Standard CS-200 push button programming. This system incorporates Allen Bradley components, which not only lowers the overall cost of ownership but also simplifies maintenance. With the latest technology like Allen Bradley PLC and PowerFlex 525 Motor Drives, it ensures basic yet effective control of encapsulation processes.

Tablet Press Retrofittable Control System Upgrade

CCS customized our standard CS-1000 programming to take full advantage of all functions that are utilized on the Fette 3090 and 2090 including the removable turret function which, with one button, the press automatically moves rolls into position so the turret can be removed. The CS-1000 control system also provides force monitoring, automatic weight control, tablet rejection and tablet sampling. A calibration page was added to the system so all positions on the press can be calibrated in one step

Stokes Model 560

10 ton, Single sided with pre-compression, Accepts B and D tooling, Maximum tablet diameter is 25 mm

Stokes Model 720

10 ton, Double sided with pre-compression, Accepts B and D tooling, Maximum tablet diameter is 25 mm

Stokes Model 328

10 ton, Double sided or Single sided with pre-compression, Accepts 328 type tooling, Maximum tablet diameter is 30 mm

Stokes Model 334

15 ton, Double sided or Single sided with pre-compression, Accepts 334 type tooling, Maximum tablet diameter is 50 mm

Stokes Model 747

8 ton, Double sided with pre-compression, Accepts B tooling, Maximum tablet diameter 16 mm, Designed for remote control application

Stokes Model 516

15 or 20 ton, Double sided or Single sided with pre-compression, Accepts DD2 tooling, Maximum tablet diameter is 75 mm

Stokes Model 557

15 or 20 ton, Single sided with deep fill option, Accepts DD2 tooling, Maximum tablet diameter is 75 mm

Stokes Model 550

12 ton, Single sided, Accept 550 tooling, Maximum tablet diameter is 30 mm

Stokes Model 512

4 ton, Single sided, Accept 512 tooling, Maximum tablet diameter is 16 mm

Stokes Model 591

5 ton, Single station, Accepts B, D and special tooling, Maximum tablet diameter 25 mm

Stokes Model 511

1.5 ton, Single station, Accepts 511 tooling, Maximum tablet diameter is 12 mm

Stokes Model 526

20 ton, Single station, Accepts 526 / R4 tooling, Maximum tablet diameter is 75 mm

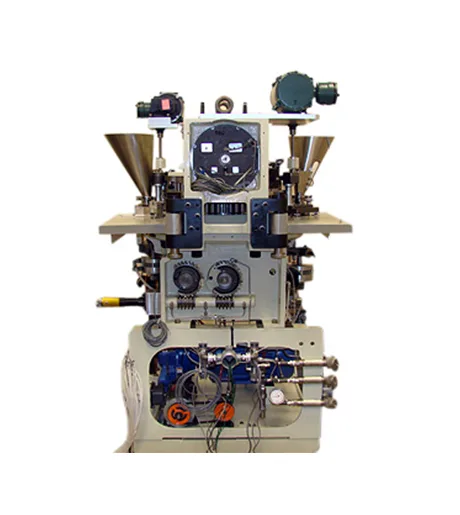

Control Systems

Control Systems for Any Brand of Old and New Tablet Presses