Design Features

- Four column heavy duty structure provides great stability and low noise levels

- Removable turret

- Fully-automatic press: lower rolls and fill cams adjusted by servo motors

- Sealed roller bearings in all pressure rolls eliminate oil leaks in rolls

- Mechanical feed system forces material into die increasing production output

- Upper and lower die table dust collection with die table scrapper keeps press clean longer

- Automatic punch lubrication ensures long life of tooling and cams

- Cleanly designed hopper and butterfly valve assembly prevents loss of powder

- Extra-large hopper opening helps material flow

- Enhanced lighting in upper and lower sections for better visibility

- Equipped with OSHA approved safety interlocks

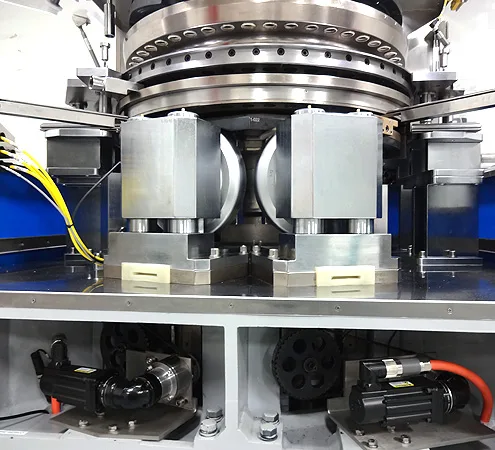

RIGID CONSTRUCTION

- Isolated compression zone keeps press clean

- Allen Bradley Servo Motors for lower rolls and fill cams with accurate encoder position feedback

Servo drives

- All compression stations (pre and final) use identical components to reduce spare parts inventory

- Four LED lights illuminate the compression zone for clear observation during production and cleaning

- Dual level, three paddle mechanical feeder design maintains powder head pressure for uniform filling of the dies

- Wide opening inlet improves powder flow ability on difficult powders at higher production speeds

- Colored lights mounted in the press frame illuminate the doors to indicate tablet press status

- Stack light not required

- Heavy Duty upper doors eliminate door vibrations for quiet operation

Optional CS Control System is designed with all Allen Bradley components for an economical control system (which can be retrofitted to any make and model of tablet press) lets you:

- Increase efficiency

- Increase reliability

- Increase performance

- Increase safety

Technical specifications

| Model | BB-83 | B-65 | D-51 |

|---|---|---|---|

| No. of Punches | 83 | 65 | 51 |

| RPM Speed (min-max) | 8-80 | 8-80 | 8-80 |

| Max. Output (tablets/h) | 796,800 | 624,000 | 489,600 |

| Max. Tablet Dia. (mm) | Ø13 | Ø16 | Ø25 |

| Die Dia. (mm) | Ø24 | Ø30 | Ø38 |

| Motor Power (KW) | 15 | 15 | 15 |

| Main pressure (KN) | 100 | 100 | 100 |

| Pre-pressure # 1 KN | 100 | 100 | 100 |

| Pre-pressure # 2 KN | 100 | 100 | 100 |

| Max. Filling Depth | 16 | 16 | 20 |

| Dia. of Punch (mm) | 19 | 19 | 25.35 |

| Pitch Circle Diameter (mm) | 720 | 720 | 720 |

| Weight (Kg) | 4800 | ||

| Dimension (mm) (L x W x H) | 1310 x 1310 x 2070 | ||