Use CCS' standard CS-2000 programming to take full advantage of all functions on all models of Stokes tablet presses or adapt the CS-2000 Control System to any tablet press made by any OEM.

The CS-2000 control system incorporates all off-the-shelf Allen Bradley components, lowering the total cost of ownership of the tablet press or control system upgrade. This makes the system easy to maintain while simplifying the sourcing of replacement electrical components.

This control system has been designed with the latest technology, using Allen Bradley ControlLogix PLCs and a FactoryTalk View HMI software interface. The system provides complete control of the tablet press. The system also complies with 21 CFR Part 11 for data collection and E-Signature.

Design Features

- Complies with 21 CFR Part 11 for secure data gathering and electronic signatures.

- Enables connecting and managing multiple tablet presses in a network.

- Facilitates remote diagnostics and control of PLC and HMI through a VPN web port.

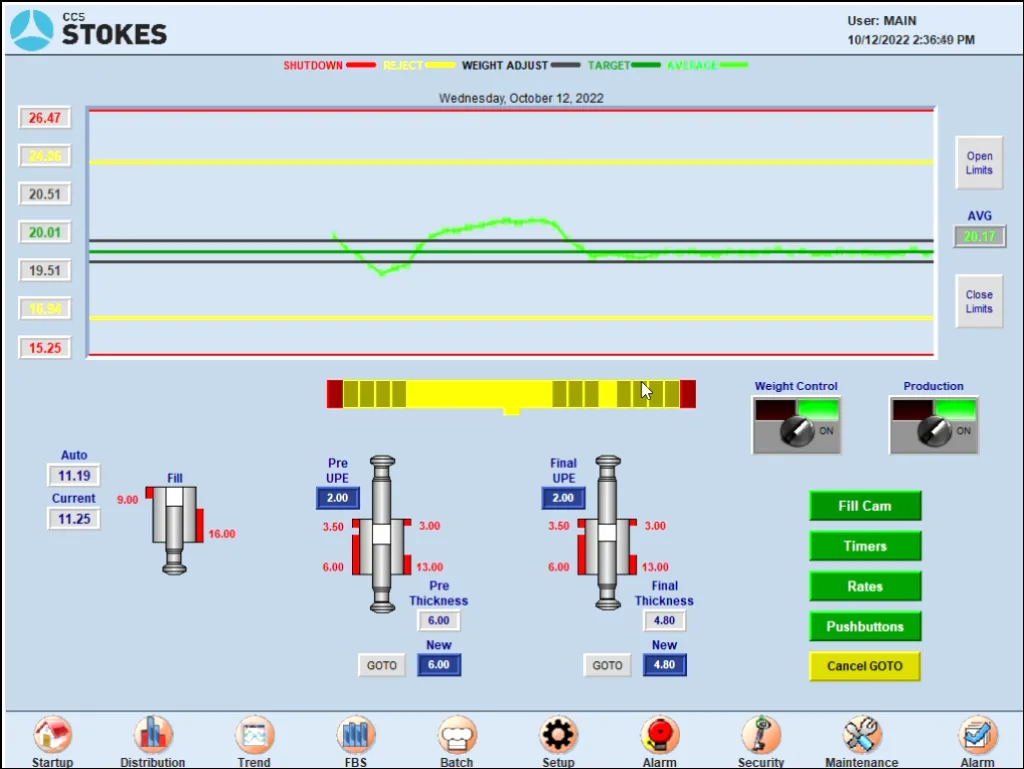

- Displays key metrics like compression force and weight adjustment limits graphically.

- Offers precise static calibration via an HMI Calibration Screen.

- Automatically discards tablets that don't meet specifications, with sample testing.

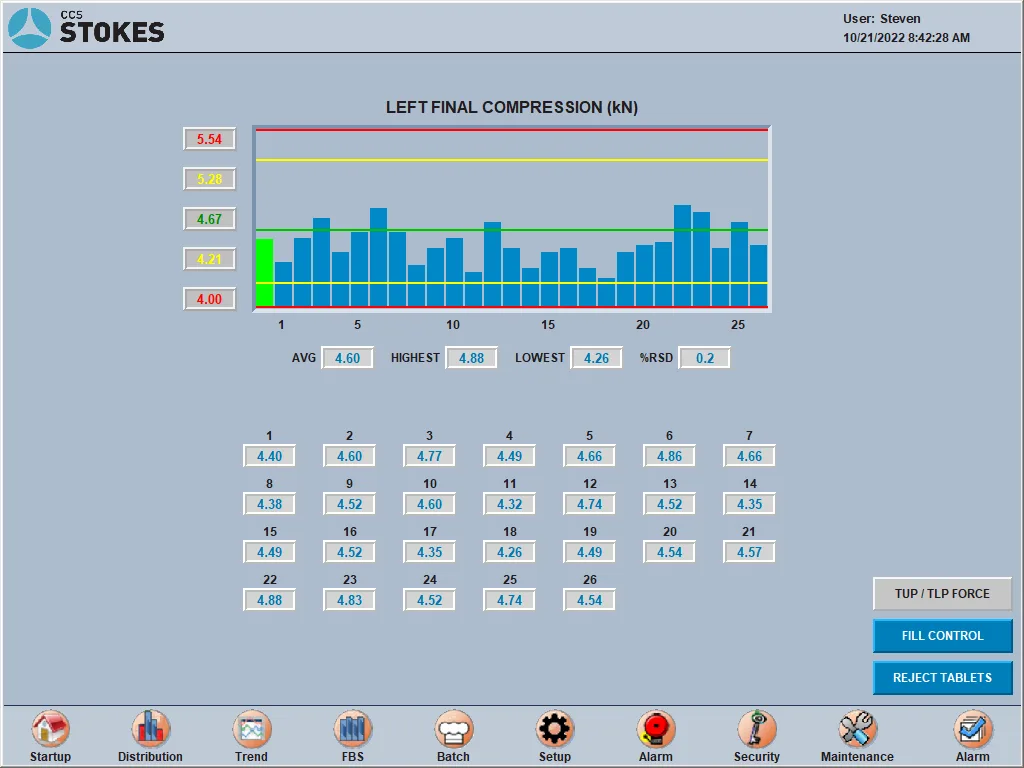

- Provides detailed performance statistics from each punch station.

- Includes a dynamic bar graph displaying punch station force for each compression roll.

- Features a distribution graph for monitoring tablet weight per batch.

- Allows separate control of each side of the tablet press for production and weight regulation.

- Offers adjustable security levels for maintenance, supervisory, and operational access.

- Integrates an alarm summary screen to notify about shutdowns and process issues.

- Displays essential operating parameters such as positions, rates, pressures, and timers.

- Utilizes Allen Bradley components for HMI, PLC, VFD, and Servo Drives.

- Includes all necessary programming software and documentation.

- Our Control Systems are designed with non-proprietary, off-the-shelf components allowing for high reliability and low cost replacement parts which are easy to source.

- Advantech Industrial PC with Windows 10 Pro

- Allen Bradley ControlLogix PLC with L81E Processor

- Allen Bradley High Speed Analog Inputs for Force Feedback

- Allen Bradley PowerFlex 525 Variable Speed Drives

- Allen Bradley Contractors, Overloads and Power Supplies

- Daytronic Signal Conditioning Modules with Peak Hold

- Allen Bradley Industrial UPS for PC, PLC and HMI.

- Netbiter Remote VPN for Secure Remote Access

- All positions are controlled using servo drives and motors.

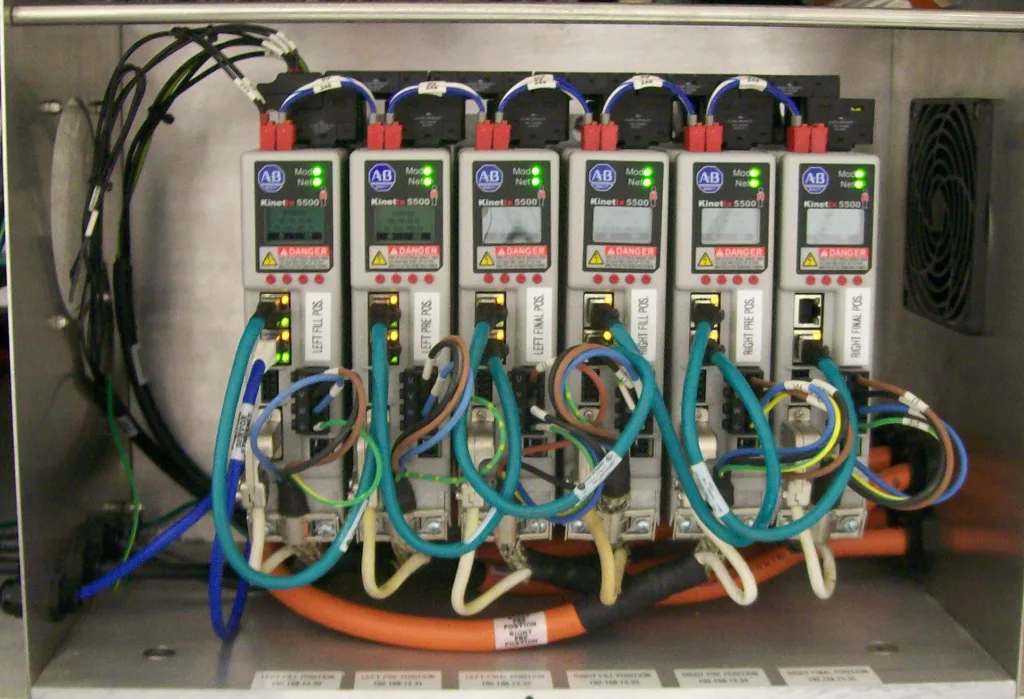

- Allen Bradley Kinetics 5500 Servo Drives

- Allen Bradley MPL Servo Motors with APEX gearboxes

- Servo Motors have precision encoder feedback for excellent position and fill control within 0.01 mm accuracy.

- Weight Control

- Production

- Reject Limits

- Shutdown Limits

- Force Feedback

- Forces By Station

- %RSD

- Individual Station Force Values

- Fill Control

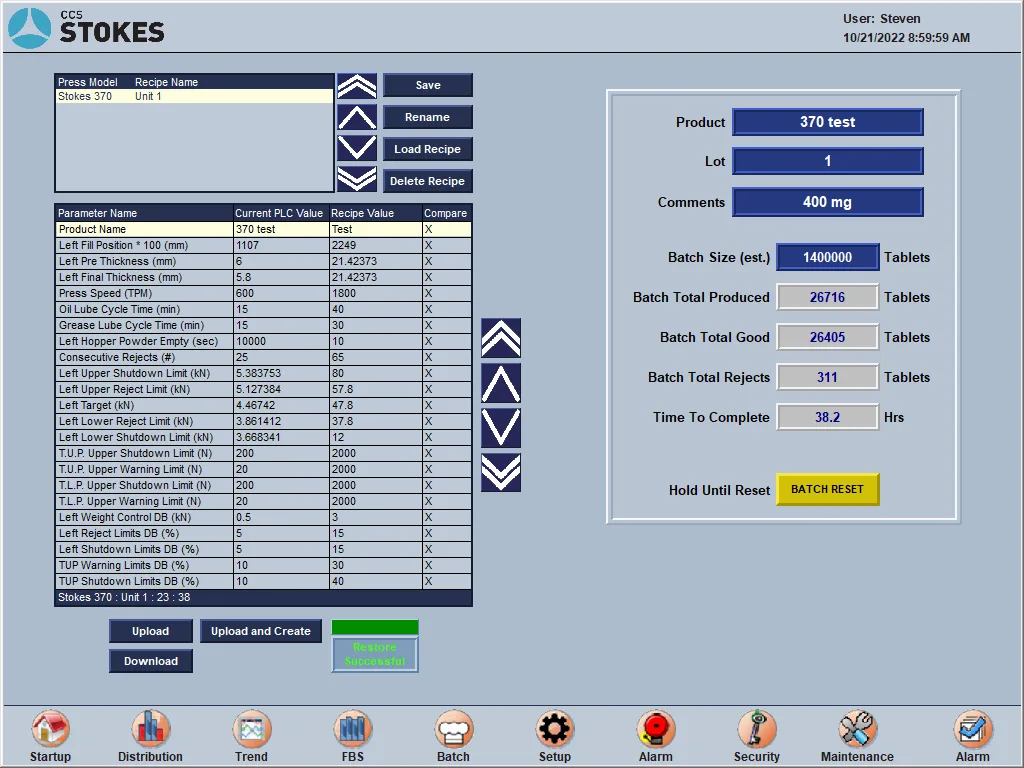

- Batch Control

- Recipes

- Current Values vs. PLC Values

The CCS CS-2000 Level 4 offers a comprehensive control system for various tablet presses, including Stokes models and other OEM devices. This system utilizes Allen Bradley components, which reduces ownership costs and simplifies maintenance. It's designed with the latest technology, including Allen Bradley ControlLogix PLCs, and ensures complete control over tablet press operations. Compliant with 21 CFR Part 11, it guarantees secure data collection and electronic signature management. The system's highlights include an Advantech Industrial PC, high-speed analog inputs, servo drives and motors for precise control, and a Netbiter Remote VPN for secure remote access, all contributing to its efficiency and accuracy in tablet production.