Design Features

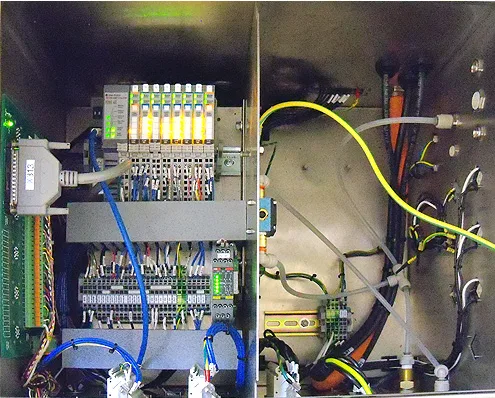

The CS-1000 control system incorporates all off-the-shelf components lowering the total cost of ownership of the tablet press by making the system easy to maintain while simplifying the sourcing of parts.

The CS-1000 control system has been designed with the latest technology that results in a system that is easy to operate and maintain. Utilizing Allen Bradley ControlLogix PLC and GE Proficy’s iFix software interface the system provides complete control of the tablet press. The system complies with 21 CFR Part 11 for data collection and E-Signature.

The CS-1000 control system has been designed with the latest technology that results in a system that is easy to operate and maintain. Utilizing Allen Bradley ControlLogix PLC and GE Proficy’s iFix software interface the system provides complete control of the tablet press. The system complies with 21 CFR Part 11 for data collection and E-Signature.

Design Advantages

- High-reliability and cost-effective parts due to non-proprietary component use.

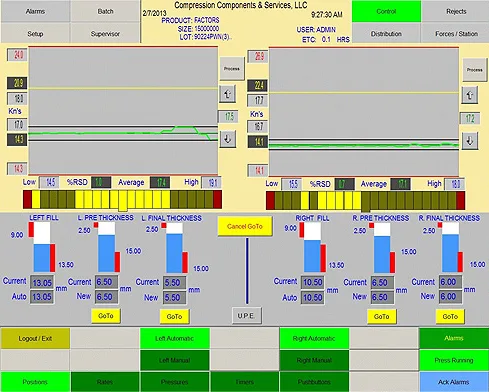

- Simplified operator training with an intuitive user interface.

- The graphical interface supports operator multitasking.

- Ethernet capabilities for data transmission from multiple presses to a server.

- System capabilities include mass diversion and sample sorting.

- Customizable and exportable reporting with XL reporter.

- Meets 21 CFR Part 11 standards for Electronic Signature and Data Collection.

- Redesigned connectors on tablet press back panel for clarity and organization.

- Single-sided tablet press components consolidated in one cabinet.

- Revamped Fette drawer with cleaning, repair, and rewiring.

- Space-saving wall mount HMI with industrial keyboard and mouse; other configurations available.

- Maintenance screen shows motor/encoder info, position stops, and probe status.

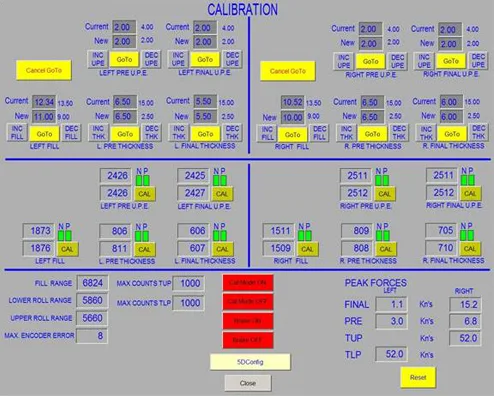

- Easy-to-use Calibration Screen.

- Automated roll positioning for turret removal at a button press.

- Peak force display at each tool station with reference to target and limit values.

- Alarm keys for quick display of press and process conditions.

- New connectors to the back panel of the tablet press are organized and clearly marked.

- All components required for a single sided tablet press can be neatly arranged in one cabinet.

- The Fette pull-out drawer will be cleaned, fixed and completely rewired.

- The wall mount HMI containing industrial keyboard and mouse reduces floor space required in production room. Other HMI configurations are also available.

- Maintenance screen displays information for the ten position motors/encoders, the N and P stops for each position and time probes status.

- Convenient Calibration Screen.

- With the touch of a button the press automatically moves rolls into position so the turret can be removed.

- Forces/station key displays the peak force generated at each tool station relative to the Target Value, the Reject Limits and the Shutdown Limits.

- Updated each revolution

- Alarm summary with automatic shutdown and warning features

- Alarm keys, when pressed, displays the alarm condition for the press and process function

The CS-1000 control system incorporates all off-the-shelf components lowering the total cost of ownership of the tablet press by making the system easy to maintain while simplifying the sourcing of parts.

The CS-1000 control system has been designed with the latest technology that results in a system that is easy to operate and maintain. Utilizing Allen Bradley ControlLogix PLC and GE Proficy’s iFix software interface the system provides complete control of the tablet press. The system complies with 21 CFR Part 11 for data collection and E-Signature.

The CS-1000 control system has been designed with the latest technology that results in a system that is easy to operate and maintain. Utilizing Allen Bradley ControlLogix PLC and GE Proficy’s iFix software interface the system provides complete control of the tablet press. The system complies with 21 CFR Part 11 for data collection and E-Signature.