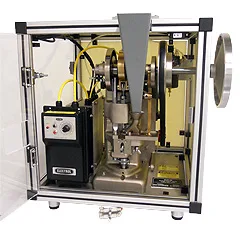

Quick and Easy Setups:

The full size hinged front panel and removable hopper allow unobstructed access for tool installation and press adjustment.

Positive Pull Down

Accurate repositioning of the lower stationary punch is accomplished immediately after the compact ejects from the die.

Standard Variable Speed Drive

Press speeds can be adjusted to suit operational requirements.

Force Monitoring

Compression and die force monitoring is available.

EnhanceD Die Table

The newly designed stainless steel die table helps contain scraped off powder so product yields are greatly improved; an excellent feature when running expensive products.

Technical specifications

| Production Rate (compacts/minute) | 40-75 |

| Maximum Tablet Diameter | 1/2 |

| Maximum Depth of Fill | 7/16 |

| Maximum Operating Pressures (tons) | 1-1/2 |

| Machine Height (in.) | 26-1/2 |

| Floor Space (in.) | 24 x 24 |

| Net Weight (lbs) | 275 |

| Service Requirements | 110 volt, Single Phase, 60Hz |