Design Features

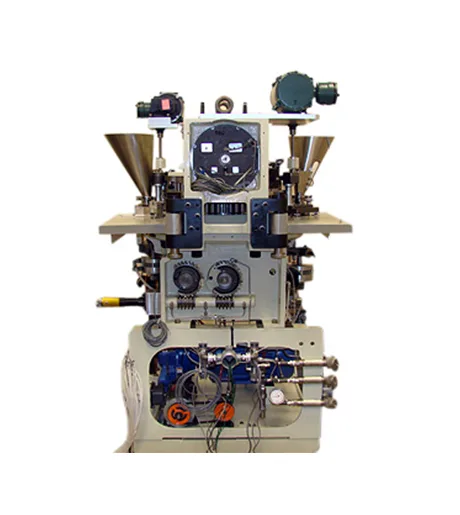

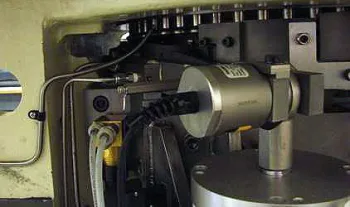

- Replace gravity feeders with motor driven mechanical feeders to improve die filling and increase press speed

- Star wheels in feeder housing forces powder into die

- Low powder hopper sensor

- Motor mounts on top of press

- Easy removable coupling used to drive feeder

Replace gravity feeders with motor driven mechanical feeders to improve die filling and increase press speed. Starwheels in feeder housing forces powder into die.

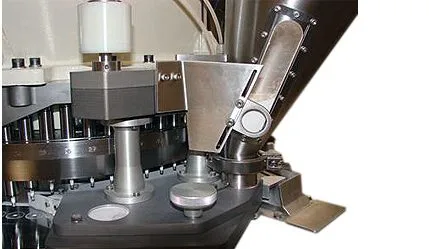

Lower punch seals can be supplied on new turrets; lower seals are located in retainer ring for easy installation. Upper punch seals also available. Punches will stay clean longer, extend life of punch.

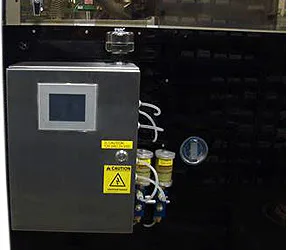

Retrofit press with auto lube system to supply oil to both upper and lower punches. This feature, along with the punch seals will extend life of punches and cams and allow the press to be run faster.

System provides oil to punch shank via foam roller and grease to punch heads via grease block. Lubrication automatically supplied via pre-set timer.

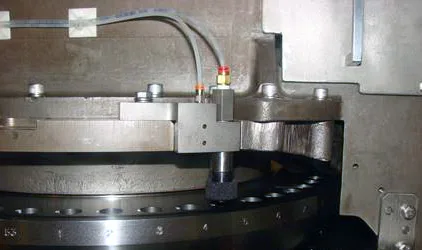

Tight upper punch sensor can be added to press with shut down limit if punches get tight to save punches and cams from wear.

Aprons are hinged to allow for swing-out motion that provide quick access to punches without removing feeders.

Larger stainless steel die table dust collection nozzles are now available to keep press cleaner, longer.

1 ton of pre-compression is now available of Stokes Model 747 presses. Only available on new machines

Previous

Next