features include:

- Extremely durable press due to rugged design

- Easy to operate and maintain

- Replacement parts are economical and in stock

- Sealed rollers bearings in all pressure rolls

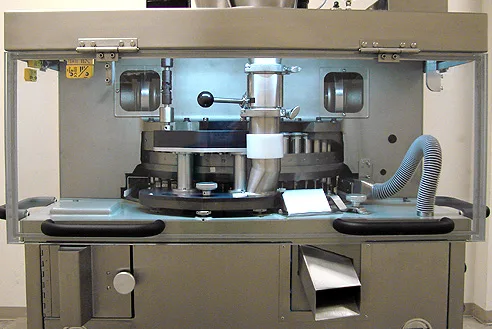

- Improved upper and lower die table dust collection

- Improved upper punch lubrication system with timed delivery

- Heavy duty upper enclosure without corner post provides better access for cleaning

- Hopper and butterfly valve assembly are designed for clean operations

- Digital tachometer provides accurate speed rate

- Upgraded non-contact door interlocks

- Enhanced lighting in both tool entry locations

- Model 328 can be upgraded to 15 tons for high tonnage applications

- Press is available manual (hand operation) or fully automatic based on the application

- Optional control system, automatic punch lubrication, mechanical feeders, bi-layer tablet kit and core rod kit

Optional CS Control System is designed with all Allen Bradley components for an economical control system (which can be retrofitted to any make and model of tablet press) lets you:

- Increase efficiency

- Increase reliability

- Increase performance

- Increase safety

Uses neck-less punches that creates larger head flat that increases dwell time on hard to compress powders

Technical specifications

| Number of tool sets | 45 | 33 |

| Type of tooling | 328 | 328 |

| Maximum tablet dia. (in) | 0.75 | 1.187 |

| Turret speed range (rpm) | 18-50 | 18-50 |

| Output of tablet (per min) | 1600-4500 | 1200-3300 |

| Fill depth - standard (in) | 0.6875 | 0.6875 |

| Fill depth - maximum (in) | 1.375 | 1.375 |

| Max. compression force (tons) | 10 | 10 |

| Power (H.P.) | 7.5 | 7.5 |

| Footprint (in.) | 52 x 46 | 52 x 46 |

| Overall height (in.) | 67 | 67 |

| Net weight (lbs) | 5000 | 5000 |