Design Features

- Heavy Duty Construction

- Roller bearings in all pressure rolls

- Automatic lubrication of upper and lower punches, both grease and oil can be supplied

- Punch seals

- Tight Upper Punch Sensor

- Heavy Duty Enclosure

- Enhanced Press Lighting

- Dust Collection System

- Hopper shut off valve

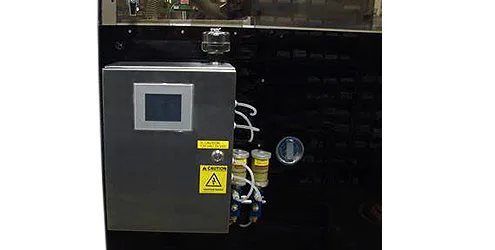

- Control System Housing Options

- Automatic lube system to supply oil and grease to both upper and lower punches and cam tracks – controlled via CS control system.

- Sealed roller bearings for extended pressure roll life – eliminates oil leaks

Enhanced die table

- Stainless Steel Nozzle mounted to press frame

- Delrin scraper cleans die table

- One for each side of press

- Connects to vacuum hose to press dust collection manifold (3”)

New style heavy duty enclosure with no post design for easy access to clean press. Enclosure combined with dust control system keeps press clean for longer runs.

Optional CS Control System is designed with all Allen Bradley components for an economical control system (which can be retrofitted to any make and model of tablet press) lets you:

- Increase efficiency

- Increase reliability

- Increase performance

- Increase safety

Technical specifications

| 15 ton machine |

| 17 stations, double sided |

| Projected output (TPM) = 340 |

| RPM range = 5 to 40 |

| Fill depth - standard (in) = 0.6875 |

| Fill depth - maximum (in) = 1.375 |

| Weight = 5,500 |

| Dimension = 51” x 48” x 72”h (see drawing) |

| HP = 15 HP Motor |

| Vacuum = 6 nozzles each require 50 CFM at 2” static pressure |

| Tooling type = designed for Model 334 – smaller than existing Model 523 tools |